Can You Afford The Cost of Tool Re-runs Due to the Inexperience of Your Benchmarking Contractor??

60% of all errors related to the placement of AGMs are a direct result of the contractor’s failure to accurately locate the pipeline and/or probe each AGM location and identify whether the AGM is on the pipeline being pigged. Because many rural ROWs are not properly maintained, there is often no way to “site in a line” and place the markers between road crossing signs or other permanent markers. The fact that many sign posts are not actually located on the pipeline, combined with unknowns such as PIs and misidentified ROWs, compounds the errors that can be made by not physically locating the pipeline at each AGM location.

Experience has proven that pipeline markers can’t be trusted as a method of accurately identifying pipeline locations. Markers are sometimes found hundreds of feet away from the actual line because the perceived right-of-ways tend to shift over the years due to changes in mowing and/or clearing patterns.

Experience has proven that pipeline markers can’t be trusted as a method of accurately identifying pipeline locations. Markers are sometimes found hundreds of feet away from the actual line because the perceived right-of-ways tend to shift over the years due to changes in mowing and/or clearing patterns.

40% of all errors related to AGM placement are because requirements such as maximum pipeline depth, minimum distance away from casings and maximum distance away from the pipeline to complete data transfer were ignored or not taken into consideration.

How We Prevent Such Costly Mistakes

Since the inception of our company in 1985, Alpha has established over 10,000 miles worth of above ground markers. Our ability to establish identifiable sub-meter, sub-2 centimeter and sub-centimeter above ground markers on land, across swamps, bays, lakes and rivers has uniquely qualified our company for some the nation’s most difficult projects. All of our AGM projects are field coordinated by at least one, and sometimes multiple, senior technicians depending on the complexity of each project. Each of our technicians, who are full-time employees with an average of over seven years with our company, are hired and promoted based on their field competency, proficiency, attitude and safety performance. All of our senior technicians have been OQ-certified, trained and tested in the use of the latest Global Positioning Satellite equipment, computerized data generation systems, and the standard requirements of the major intelligent tool manufacturers.

Our OQ procedures, which are more stringent than required, also assure that the most qualified technicians are provided for your project. As part of our corporate operator qualification procedures, each of our technicians is trained and then given a written examination that includes the requirements of the major tool manufacturers for AGM placement.

Our OQ procedures, which are more stringent than required, also assure that the most qualified technicians are provided for your project. As part of our corporate operator qualification procedures, each of our technicians is trained and then given a written examination that includes the requirements of the major tool manufacturers for AGM placement.

Ensuring Accuracy

Our technicians are capable of identifying and establishing AGM locations, based on the mileage spacing requirements of the tool manufacturer, using only lines sheets as a guide to each AGM site. This allows our crew to work independently with little to no field supervision from our clients.

Through our over seventeen years of experience in setting both temporary and permanent AGMs, we have established solid relationships with many of the major intelligent tool manufacturers. These relationships, combined with our experience in tracking their tools runs, have enabled our technicians to become experts in the location requirements of the manufacturers’ data collection boxes.

As part of our standard operating procedure, all pipelines are electronically located and probed to ensure that the dimensions of the line at the proposed AGM location meets the specifications of the line to be pigged. As part of our coordination procedures, each intelligent tool manufacturer is contacted by our project planning personnel (or sales manager) before project mobilization and documents the AGM placement requirements for each tool to be run. These requirements are then passed to our technicians to ensure that minimum and maximum AGM location requirements are not exceeded. Ignoring these requirements, or failing to ensure that all locations meet the requirements, will cost hundreds of thousands of dollars in tool re-runs.

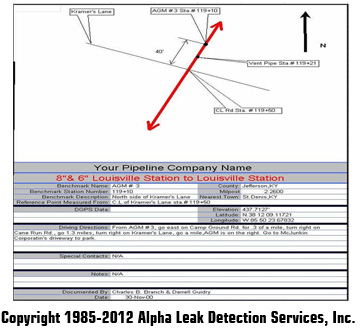

Computer Generated AGM Data Sheets and Routing Maps

As part of our procedures, each AGM location is documented on a computer-generated data sheet. Each data sheet contains such information as an AGM location map with GPS coordinates, driving time, directions from the last sequential AGM location, special access information and pipeline depth of cover. Because Alpha tracks hundreds of pigs each year, our technicians are keenly aware of the minimum data that should be transferred to pig tracking contractors for each AGM. Although minimum requirements are sufficient to give a description of the AGM location, they are not sufficient to ensure that each AGM location is reached during the pig run.

As part of our available data collection packages, our technicians can prepare a summary of all AGM locations, computerized maps of the AGM locations and the necessary access routes to each sequential AGM location. Pipeline maps are also critical for accurately tracking pigs and identifying anomaly locations found by intelligent inspection tools. Our mapping and benchmarking services are compatible because each AGM/benchmark coordinate is inserted into the map and made available at the click of a mouse.

We can also prepare a pig tracking timeline for the sequential AGM location assignment for each pig tracking crew based on pig speed, distance between AGM locations, crew sizes and access needs. To assist in completing your projects in a timely manner, each of our trucks is equipped with computer mapping stations. This enables our technicians to complete most maps at the end of each day and ensure that crucial information regarding your pipeline is in your hands faster than traditional mapping methods.

We can also prepare a pig tracking timeline for the sequential AGM location assignment for each pig tracking crew based on pig speed, distance between AGM locations, crew sizes and access needs. To assist in completing your projects in a timely manner, each of our trucks is equipped with computer mapping stations. This enables our technicians to complete most maps at the end of each day and ensure that crucial information regarding your pipeline is in your hands faster than traditional mapping methods.

Specialty Access Equipment

We maintain an arsenal of specialty equipment including airboats and motorboats that allow our crews to access the most remote pipeline locations. This equipment allows us to set AGMs and track pigs in swamps and other bodies of water. In addition to our arsenal of marine equipment, Alpha owns various 4×4 and 6×6 ATVs for remote right-of-way access. This equipment has allowed our technicians to complete some of the most demanding and time constrained projects in a minimal amount of time.

Isn’t The Risk Associated with Missing the Pig Enough to Consider using Qualified Trackers??

Simple mistakes, such as not ensuring that intelligent tool data boxes are close enough to the pipeline to collect data as the tool passes, have caused thousands of dollars in tool re-runs. Inaccurate pig-tracking data collection may also cause you to spend weeks in the field searching for the correct anomaly location.

Intelligent Tool/Pig Tracking

Since the inception of our company in 1985, Alpha has over 20,000 miles worth of pipeline in-line inspection (“ILI”) tool and pig runs. Our technicians and equipment have successfully tracked pigs on land, in swamps and across various bodies of water during the most extreme weather conditions.

We have tracked passive pigs as far as 400 miles and intelligent tools as far as 250 miles non-stop at speeds of three to five miles per hour. We have also completed projects that have required us to track pigs over 920 miles on the same system continuously. The use of various combinations of our technicians around the clock has allowed us to complete projects that are outside of the capabilities of most pig-tracking companies.

Our OQ-certified staff of senior technicians has an average of over seven years of service with our company tracking ILI tools and pigs under various conditions and with virtually all of the major tool and pig manufacturers. Our project procedures, which were developed over our many years of experience, ensure that we arrive at each AGM/benchmark location in time to verify pig passage and collect ILI tool data. One of these procedures is the preparation of AGM/benchmark access routing maps based on the coordinates gathered during the establishment of AGM locations. These maps can be created for any location in the continental United States before we mobilize for field activities. This system alone reduces the overall project cost by reducing the amount of time our crews spend in the field.

Pre-Job Analysis and Planning

Because of our many years of pig-tracking experience, our infield pre-job analysis often enables our technicians to correct the AGM/benchmark placement mistakes made by others. Our pre-job analysis also enables our technicians to identify the need for specialty access equipment that, if not utilized, would render some locations non-accessible within the allotted window of time. As part of our standard procedures, our project lead technicians consult with each intelligent tool manufacturer before mobilization to ensure that data collection box placement meets all data transfer requirements for each tool run.

We estimate and plan each project crew and shift size based on several factors to ensure the safest and most successful project. Alpha has maintained an exemplary field safety record because our standards for crew size and equipment maintenance are designed to ensure the safety of our customers and our employees.

Pig-Tracking Equipment

Our ultrasonic listening equipment is essential for tracking ILI tools, soft foam pigs, brush pigs and poly pigs used for cleaning, interfacing of product or testing. These pigs can be detected over any distance and under almost any conditions. Multiple pigs can be tracked, if required. Our technicians and equipment have successfully tracked pigs near highways, power lines, lines with deep cover, and swampy areas during the most extreme weather conditions.

Electromagnetic transmitters can be used in conjunction with our ultrasonic pig-tracking equipment. This instrument can record, download and print data such as location, time and date of all pig passes. Alpha technicians can track pigs at depths of 25 feet across land, swamps and bodies of water with a transmitter battery life of 500+ hours. The electromagnetic transmitter units are available to be attached or inserted into pipeline pigs that have a history of lodging or becoming “lost” in the pipeline. Should the pig become stuck, our technicians can pinpoint the exact location.

Pig-Locating

For ILI tools that are lost without on-board transmitters, our cesium magnetometer unit is a sound alternative. It is a proven tool for rapidly pinpointing the location of ILI tools that utilize large magnets and are lost without on-board electromagnetic transmitters. The experience of our technicians in locating stuck pigs alleviates the need of our customers assisting in these activities.

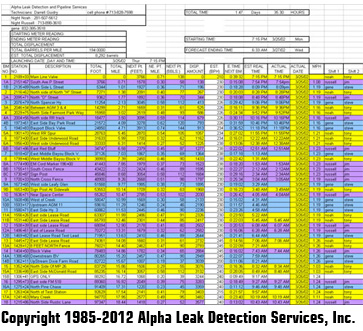

Computer-Generated Data

As part of our standard services, our technicians will prepare a pig-tracking timeline for the sequential AGM/benchmark location assignment of each pig-tracking crew based on pig speed, distance between AGM/benchmark locations, crew sizes and special access requirements. These computer-generated data spreadsheets identify such information as pipeline barrel counts (or SCFH), mileage between locations, and the estimated time the pig/tool will pass the AGM/benchmark location. Because of our preparation procedure, we are able to track pigs in inclement weather and at night.

The incorporation of all data into one electronic document ensures that all pertinent information is available instantly during each tool run. This information is also a crucial resource during the anomaly location and anomaly verification dig process. The electronic data for each project, including maps and spreadsheets of each AGM location with GPS coordinates and tracking data of each tool run, are retained by Alpha in our customer files for future tools runs on the same pipelines. Our standard method of project documentation requires that all information be created electronically in Microsoft-compatible software formats. This allows our technicians to file and send your information electronically. The use of our electronic data system ensures that all future documentation for the same pipeline system can be quickly generated without the need to re-establish AGM location maps or generate basic routing, access and tool tracking information.

Specialty Access Equipment

We maintain an arsenal of specialty equipment including airboats and motorboats that allow our crews to access the most remote pipeline locations. This equipment allows us to set AGMs and track pigs in swamps and other bodies of water.

In addition to our arsenal of marine equipment, Alpha owns various 4×4 and 6×6 ATVs for remote right-of-way access. This equipment has allowed our technicians to complete some of the most demanding and time-constrained projects in a minimal amount of time.

Estimates and Proposals

Our sales force or project planning staff will ask you a series of direct and standard questions that are designed to gather vital information to assist our field technicians in conducting a thorough pre-mobilization project analysis. This procedure ensures that our technicians arrive on you project site with the proper equipment and manpower on hand to safely and efficiently execute your AGM/benchmark project.

Click here to discuss your needs with a qualified Alpha associate.